Central tubes for satellites

ArianeGroup provides central tubes for satellites. The stability, light weight and strength characteristics of these structures are essential. ArianeGroup offers expertise in design, analysis, manufacturing, assembly and testing.

Lightweight, robust structures for optimal in-orbit performance

ArianeGroup’s central tubes are used on numerous geostationary observation satellites, such as the French Pléiades tandem or the South Korean GEO-KOMPSAT duo. The central tube is the satellite’s backbone, housing its propellant tanks and supporting the full weight of its equipment (solar panels, antenna reflectors, electronics).

Although very light, this structure must be able to withstand significant vibrations at the moment of launch and extreme thermal conditions in orbit, while ensuring a high level of stability to guarantee optimal operation of the satellite’s instruments.

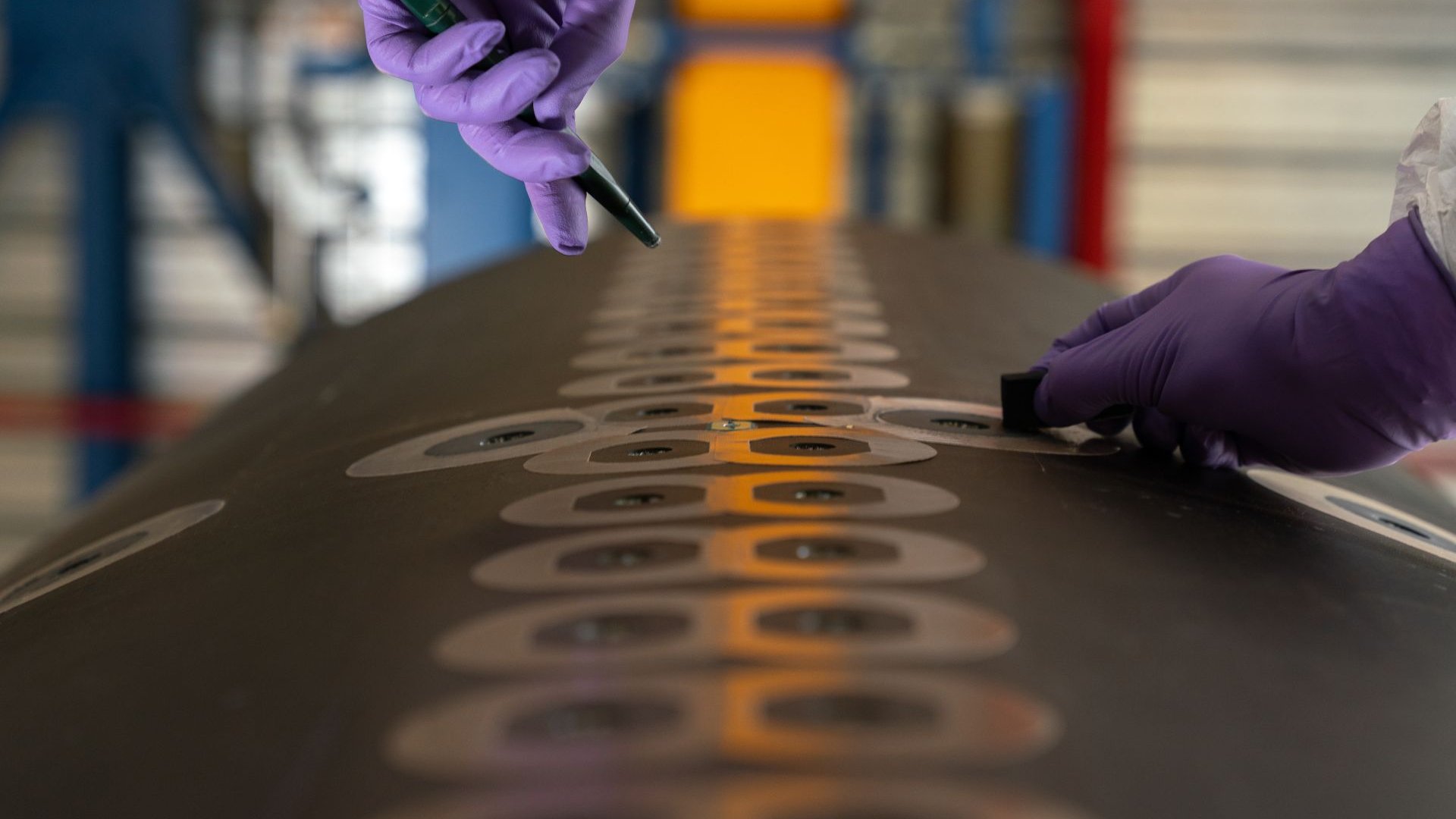

ArianeGroup central tubes made of carbon fibre reinforced polymer (CFRP) meet all these functioning needs, combining light weight with a very low thermal expansion coefficient, low density and excellent mechanical properties.

Bespoke manufacturing and a competitive edge

ArianeGroup’s central tubes are developed and produced specifically to meet the needs of each mission. Although standard structures are generally two metres long and one metre in diameter, with a wall thickness of 10–12 mm, ArianeGroup can offer solutions for satellites up to four metres in height.

ArianeGroup has been active on the satellite central tube market for more than 40 years and has already delivered nearly 100 items, for all types of customers and missions.

ArianeGroup experts use standardised processes and components in order to optimise development cycles and keep down manufacturing costs. Customers also benefit from the combined expertise of the ArianeGroup teams in a wide range of fields, such as orbital propulsion, propellant tanks and antenna reflectors.

Key features

| Dimensions | Height | m | Up to 4 m |

| Average weight | kg | 55 – 100 | |

| Materials | Sandwich structure | CFRP and aluminium honeycomb | |

| Insert/Corner/Internal deck | Aluminium or titanium | ||

| Strength | Max. load | N/mm² | 160 – 688 |

| Launcher interface | Ring | mm | 1,194 |

| Testing | ArianeGroup facilities | X-ray inspection

Ultrasonic inspection Advanced dimensional measurement system |

Download our brochures

Central tubes for satellites

Download file