Propulsion systems for launchers

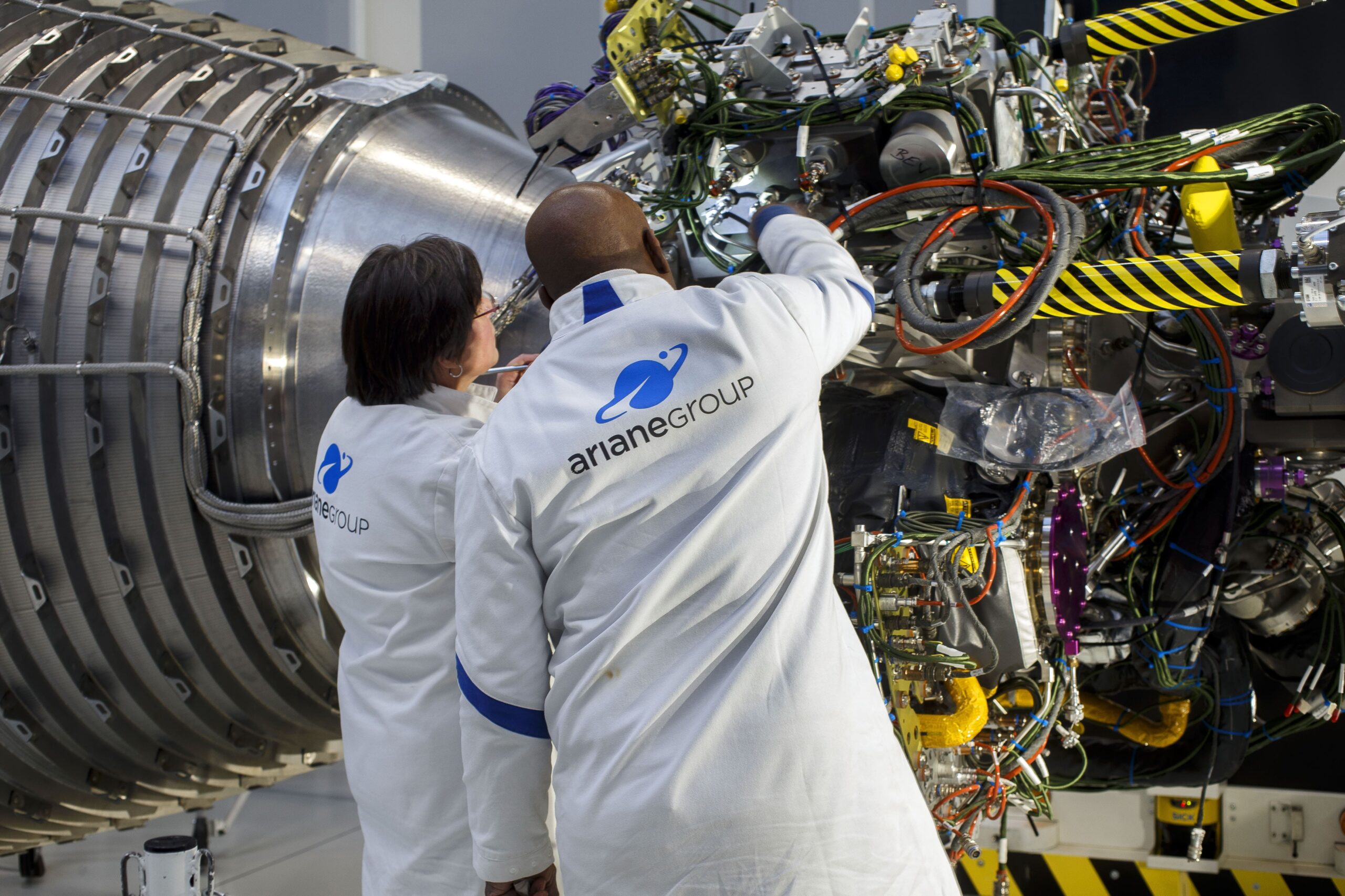

As lead contractor and design authority for the Ariane launchers, ArianeGroup has nearly 50 years’ experience of designing and producing propulsion systems.

ArianeGroup is one of the few companies in the world to have mastered all the fundamental technologies for launcher propulsion, including both solid propellants and storable or cryogenic liquid propellants (oxygen–hydrogen or oxygen–methane), for all types of launchers and stages, whether main, upper or kick stages, or strap-on boosters.

This unrivalled expertise allows ArianeGroup to offer precisely-tailored solutions for all missions.

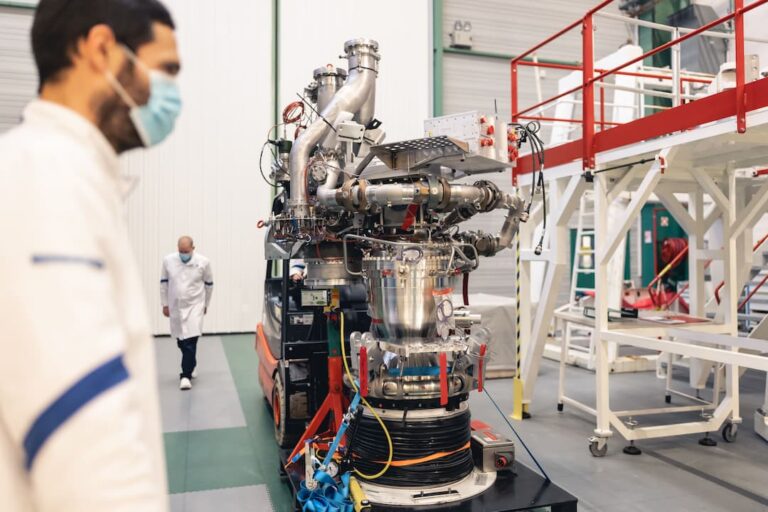

Prometheus®

Prometheus® is a cutting-edge-design reusable cryogenic engine fuelled by liquid oxygen and liquid methane (LOx/LCH4). The new standard high-thrust (>100 metric tons) rocket engine, it is designed to equip the main stages of medium-/heavy-lift launchers.

Prometheus® is the first of a new generation of engines designed for reusability. It features multiple ignition capability as well as throttling (variable thrust) capability, enabling the engine to adapt to flight conditions during the different mission phases. It also integrates intelligent on-board control systems and digitised engine control and diagnostics.

A liquid oxygen–hydrogen version of the engine is also being developed in parallel.

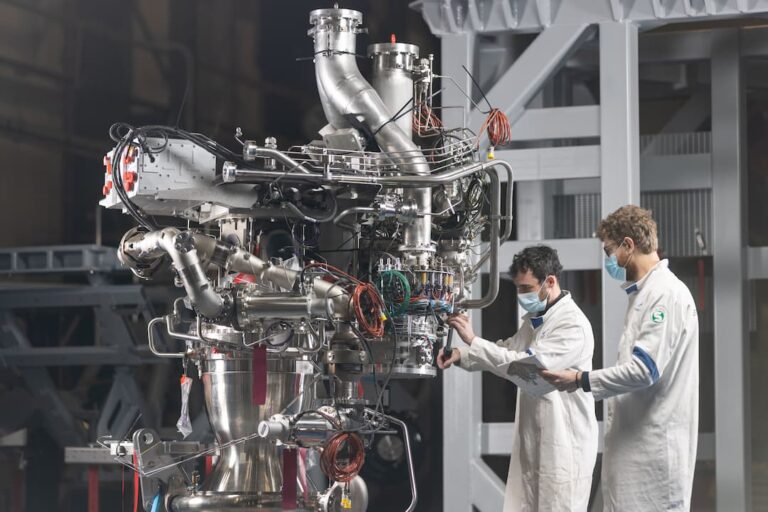

Storable Propellant Engine (SPE)/BERTA

SPE/BERTA is a high-performance new-generation 5 kN thrust class rocket engine which uses propellants that can be stored in space as liquids at roughly room temperature. This type of engine can be reignited several times, making it particularly suitable for extended missions or for transport to different orbits.

Based on technologies developed by ArianeGroup in Germany under the European Space Agency (ESA) Future Launchers Preparatory Programme, SPE/BERTA will be first used to power the Astris kick stage, a complementary additional stage for Ariane 6 which will further augment the European launcher’s versatility. Lightweight, robust, reignitable and highly efficient, BERTA provides the precise kinetic kick necessary for Astris’ missions, such as injecting satellites directly into geostationary orbit.

A modular-thrust version dubbed SPE-T (T for throttleable) is currently being designed for future moon landers.

Watch the video

Vinci®

The Vinci® engine is the 180-kN thrust upper stage cryogenic engine for Ariane 6. Its multiple ignition capability is key to the rocket’s versatility, enabling several payloads to be placed in different target orbits.

Vinci®, an expander-cycle engine running on liquid oxygen and liquid hydrogen (LOX/LH2), is characterised by high-performance oxygen/hydrogen turbo-pumps, an optimised regenerative cooling circuit for the combustion chamber, the use of manufacturing processes selected under a design-to-cost approach. It has been developed by ArianeGroup in cooperation with European partners under a European Space Agency (ESA) programme.

ArianeGroup has developed a totally innovative element for the Vinci® propulsion system: an Auxiliary Propulsion Unit (APU) which pressurises the upper stage fuel tanks and provides thrust for the satellites to be separated in clusters.

At the end of its mission, Vinci® can fire one last time to deorbit the upper stage in order to minimise space debris.

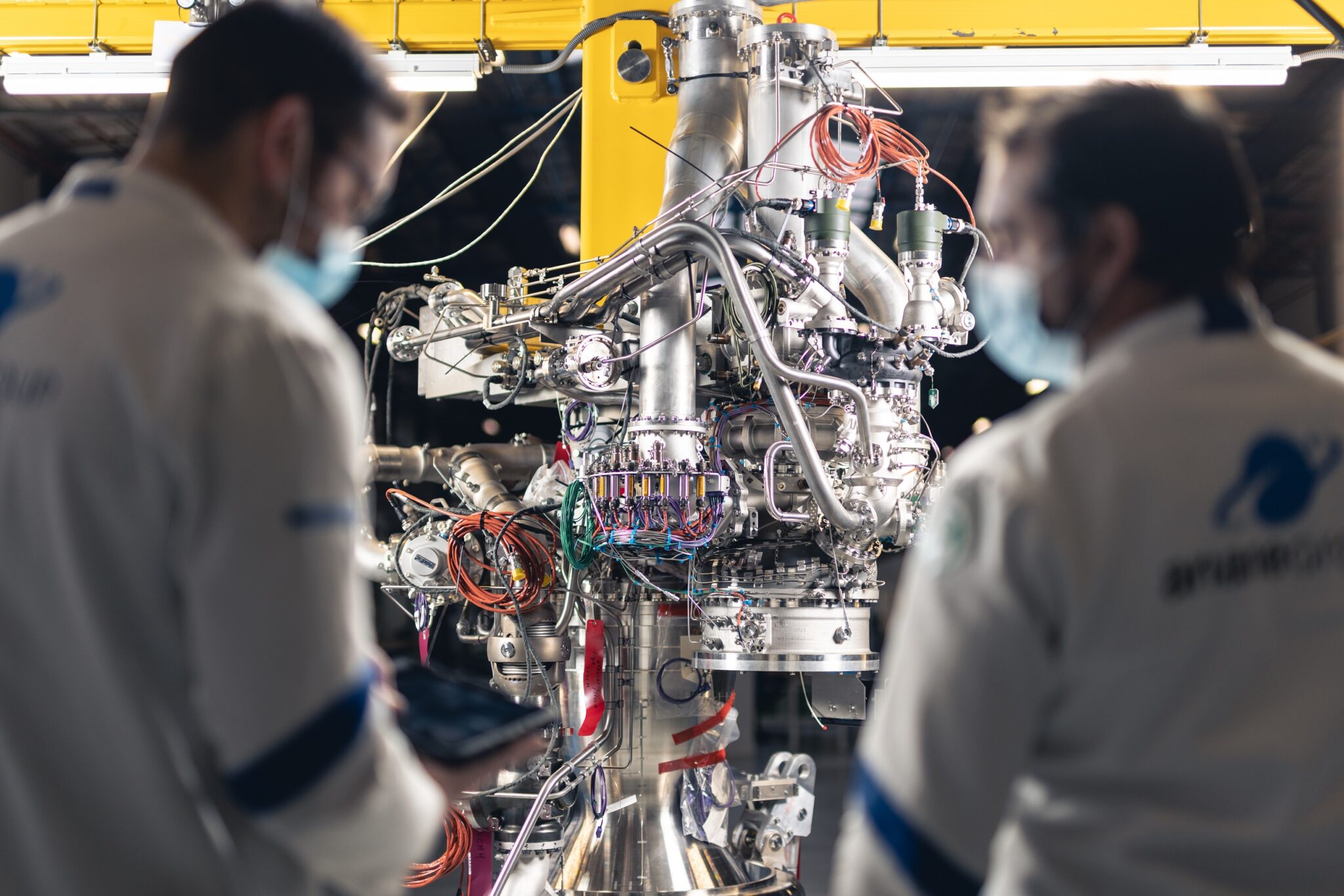

Vulcain®2.1

Vulcain®2.1 is the engine for the Ariane 6 main stage, delivering a powerful acceleration during the first eight minutes of flight, up to an altitude of around 275 km.

This cryogenic liquid-propulsion engine has been developed by ArianeGroup in cooperation with European partners on behalf of the European Space Agency (ESA). It operates by burning liquid oxygen and liquid hydrogen fuel (LOX/LH2) in a combustion chamber via a gas generator and two turbo-pumps, providing a thrust of 137 metric tons in a vacuum.

The 3.6-metre high Vulcain®2.1 is an upgraded version of Ariane 5’s Vulcain 2 engine with a number of advanced technology features, including gas generator produced by 3D printing, simplified divergent nozzle, and a new electrically-operated hot gas valve undergoing acceptance testing. Supporting ArianeGroup’s overriding aim of simplification, a new high-tech assembly line for the engine has been put in place.

Another Vulcain 2.1 performance-boosting innovation is that the combustion chamber ignition system has been moved from the engine to the launch pad.