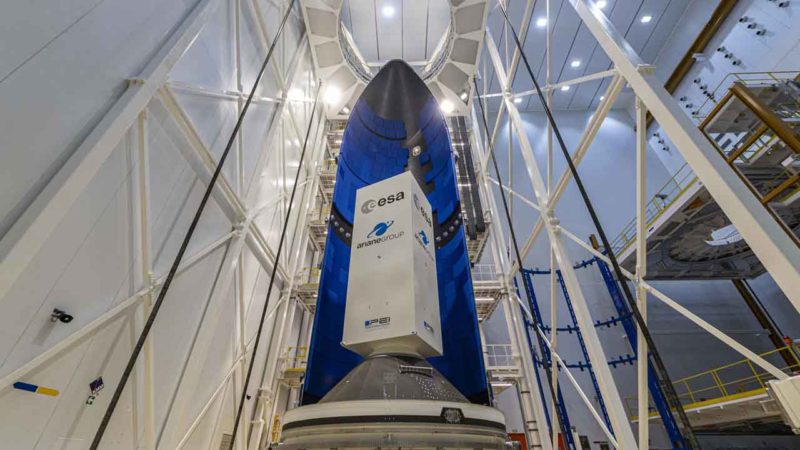

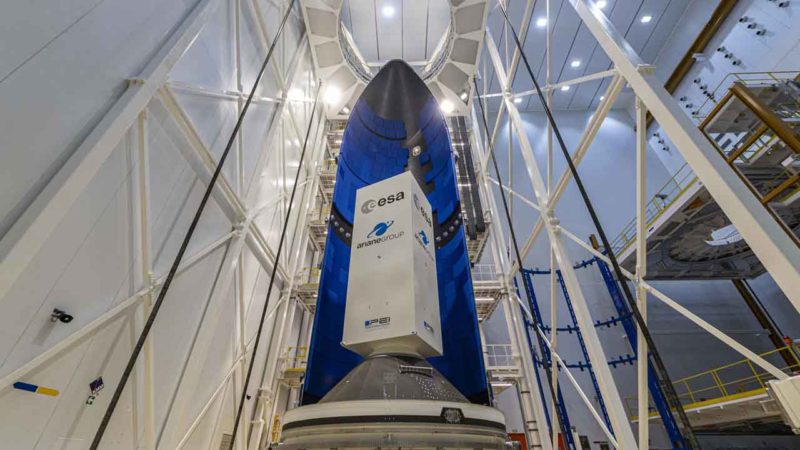

The very first Ariane 6 fairing is put through its paces at the European spaceport

19.05.2021

These pictures give an insight into the rigorous test campaign on the first Ariane 6 fairing, which will fly on one of the early missions of our new European rocket

The new fairing arrived at the European spaceport in Kourou in late April for a month of tests.

These tests, using a dummy payload, are designed to trial equipment and procedures inside the assembly building under real conditions.

These are part of the first ‘combined tests’ for proving the launch system interfaces across the entire launch vehicle and ground functions, and for rehearsing procedures.

The fairing plays a crucial role in the success of the mission. It has several purposes over and above protecting the payload from the external environment in the early stages of flight and is fundamental in the aerodynamics of the launcher due to its shape and position.

© ESA-CNES-AE-AG / CSG Service Optique – S. MARTIN

The fairing used for these tests is the long Ariane 6 fairing: 20 m high (3 m taller than that of Ariane 5). (Ariane 6 can also be equipped with a shorter fairing.)

Its dimensions necessitated an adaptation of the existing facilities – a new integration dock scaled to accommodate the new arrival (including mobile access platforms), and a new 26 m-high door.

© ESA-CNES-AE-AG / CSG Service Optique

Here you can see the new access architecture frame, with two movable platforms accessible by fixed stairways.

© ESA-CNES-AE-AG / CSG Service Optique

These tests used a real fairing and a dummy payload representing a typical satellite mass and volume. The versatile Ariane 6 will be able to accommodate all payload types from large telecoms satellites, observation satellites, nanosatellite clusters, deep space probes, and space cargo vehicles.

© ESA-CNES-AE-AG / CSG Service Optique

The installation of the dummy satellite on the adaptor – the cone you can see in the photo represents the interface between the upper payload passenger and the lower parts.

© ArianeGroup – Antoine Letellier

The fairing is composed of just two enormous half-shells manufactured from carbon-fiber composite and ‘cured’ by an out-of-autoclave process, thus reducing costs and speeding up production.

© ArianeGroup – Antoine Letellier

The blue tiles are the acoustic protection which ‘dampens’ the noise created during launch.