Orbital propulsion systems

We have developed exceptional expertise in all the different propulsion technologies, spanning solid and liquid propellants (monopropellant and bipropellant), all-electric and hybrid systems. Our solutions are tailored to the specific needs of each customer. We provide both complete propulsion systems and single thrusters, along with the necessary components and subassemblies (tanks, valves, etc.).

Brochure :

Orbital propulsion

Download file

Chemical propulsion

ArianeGroup provides chemical monopropellant and bipropellant components and complete propulsion systems for commercial, institutional and exploration (including human-rated) missions.

ArianeGroup’s expertise in the design, manufacturing, assembly, integration and test of complete propulsion systems has contributed to hundreds of successful space missions for customers worldwide. We have supplied propulsion systems for hundreds of major international satellite and spacecraft programmes, either standard off-the-shelf systems or customised systems designed and developed to precisely meet customers’ specific needs. In addition to propulsion systems based on conventional hydrazine, ArianeGroup develops propulsion systems with alternative propellants that comply with the most stringent technical, safety and environmental requirements.

Electric propulsion

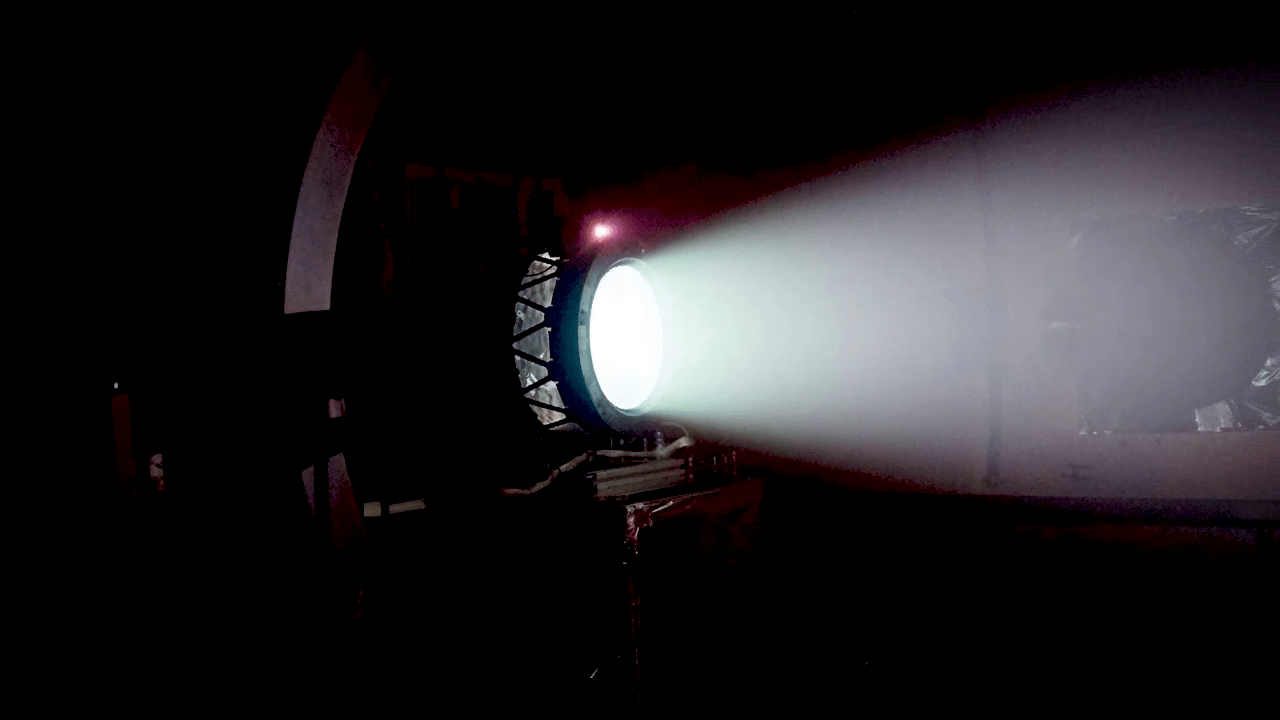

Radiofrequency ion propulsion for transfer orbit, station keeping, and deep space missions.

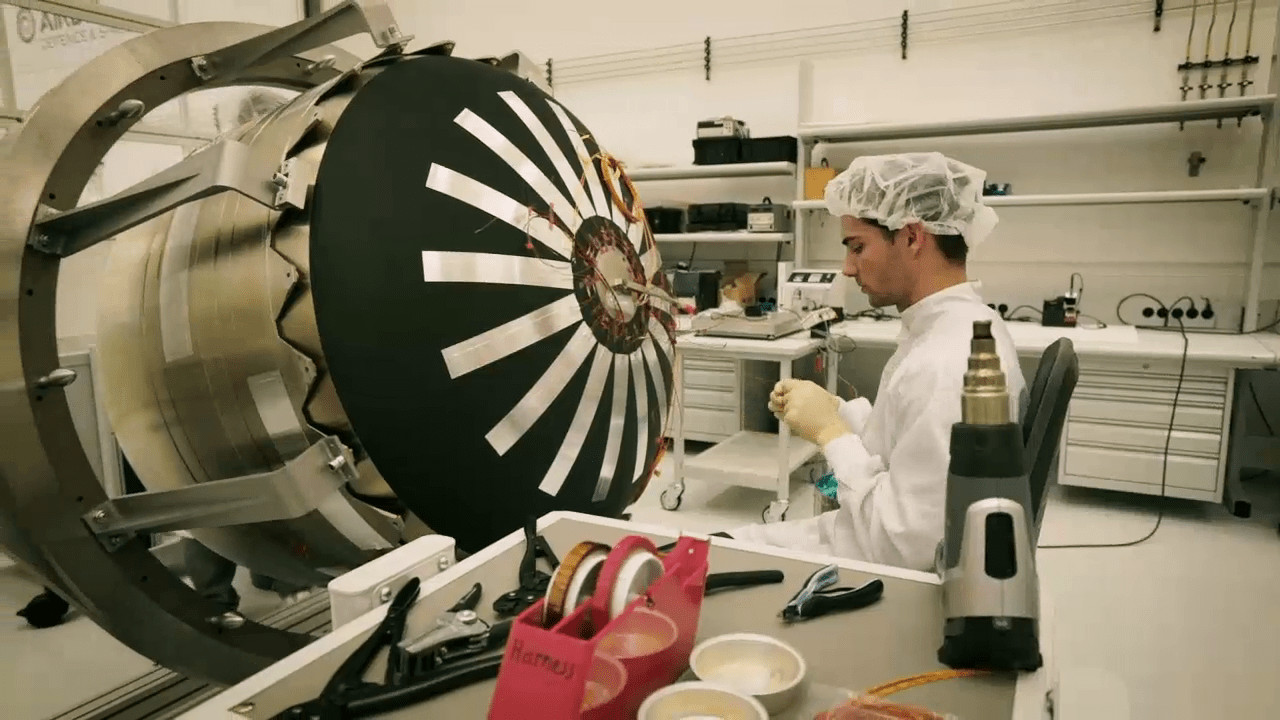

ArianeGroup’s electric space propulsion expertise is based on space-proven Radiofrequency Ion Technology (RIT). In this field, we produce complete propulsion systems, together with modules, thrusters and all related components.

This technology features numerous advantages such as high specific impulse delivers maximum propellant saving. Low system complexity is another RIT asset. Robust design concept with a large domain of operational stability, large throttle range adaptable to available electric power, excellent thrust stability, fast thrust response and narrow ion beam are all benefits that boost efficiency of any satellite platform flying with RIT, whether all-electric or hybrid. Furthermore, RIT means that operational parameters can be adjusted in orbit for mission condition optimisation – for example, it is possible to achieve a combined high thrust / high Isp mode.

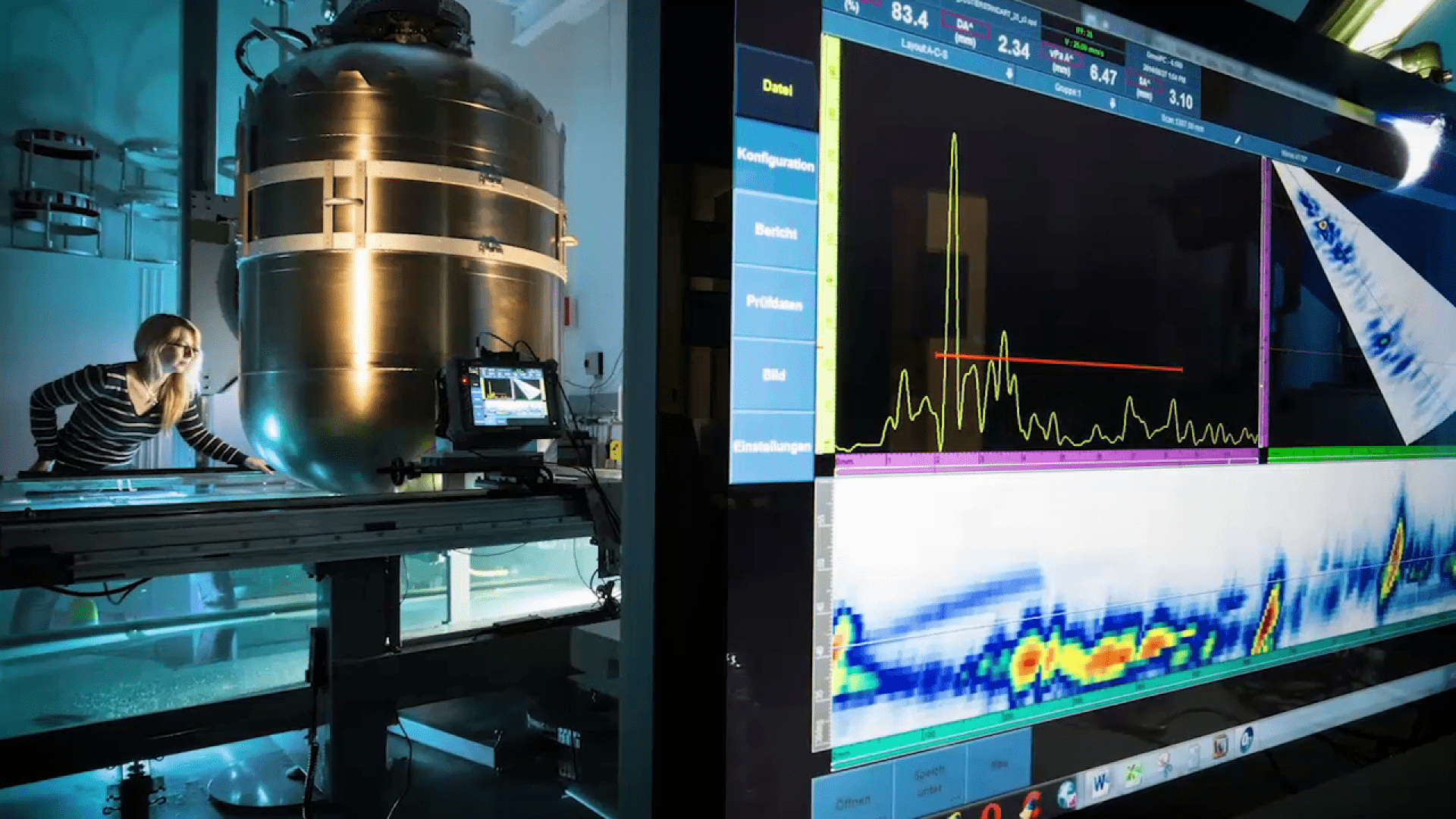

Tanks

ArianeGroup develops and produces propellant tanks for chemical monopropellant, bipropellant and launcher systems. The spectrum of different tank types includes surface tension tanks, bladder tanks, propellant tanks for spin-stabilised spacecraft, designed-to-demise aluminum-alloy diaphragm tank and tanks with liquid centre-of-gravity control. With different geometries, from spherical shell to Cassini shape and with volume capacities ranging from 58 litres to 2,100 liters, ArianeGroup tanks respond to a wide range of satellite platform requirements. Most tanks are made of titanium to ensure high load capability with low weight. ArianeGroup has created standard designs to optimise the product line, and also makes its engineering experience available for individual customer requirements.

Propellant tanks

Propellant tanks

Download file

Fluidic equipment

Valves for the fill, drain, isolation, control and regulation of propellants and pressurants.

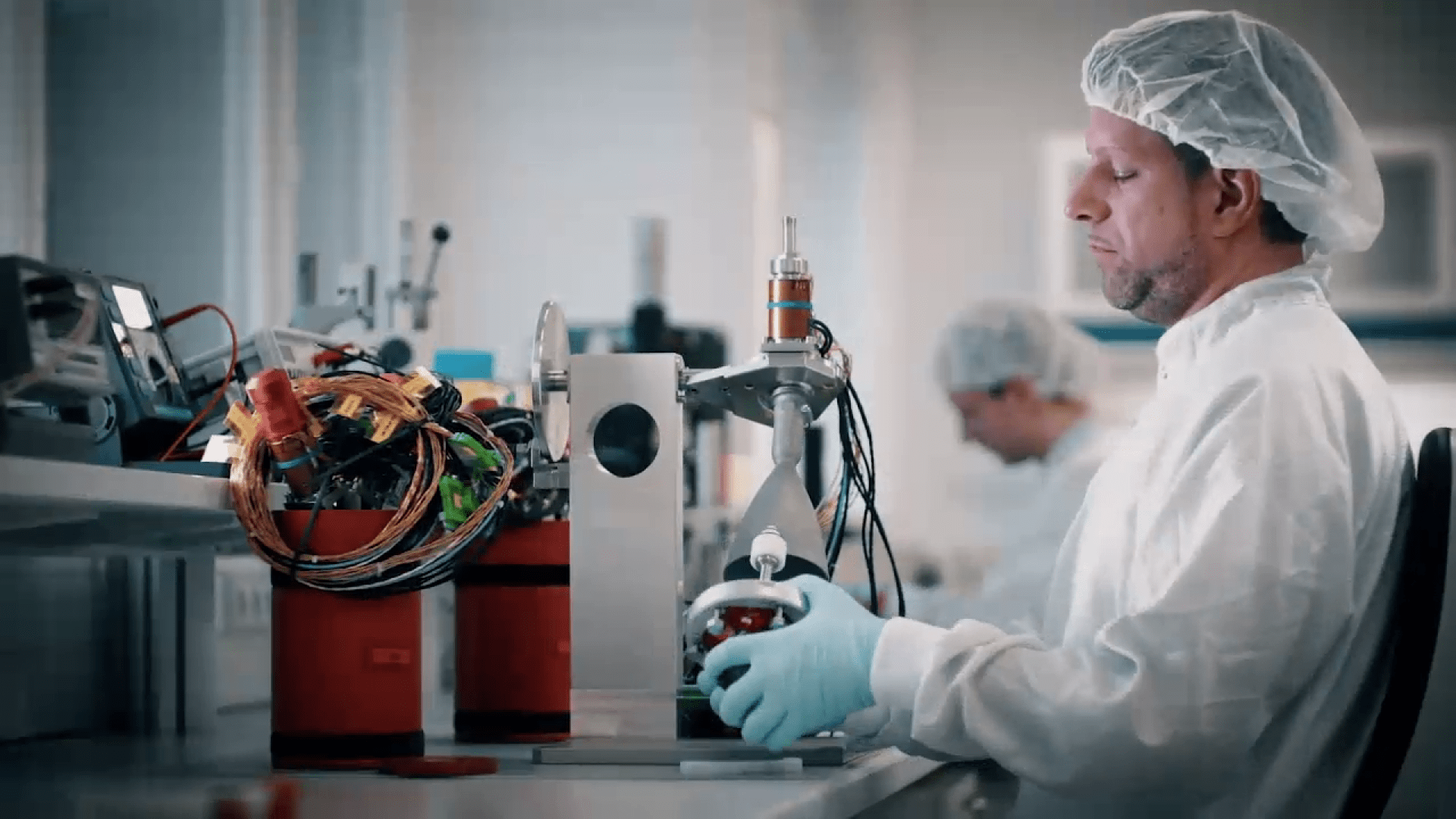

To ensure the highest possible quality, reliability and performance of our spacecraft propulsion systems and thrusters, we design, develop and produce our own valves for control of propellants and pressurants.

Services

We also apply our space propulsion expertise to a wide range of specialist support services for spacecraft and launcher propulsion which we provide both for our own programmes and for external customer projects. Our technical expertise covers equipment, facilities and management of chemical and electrical propulsion systems. Services include hot firing test facility engineering, ground equipment, propellant loading, propulsion system test and launch campaign support.

Brochure :

space propulsijon Services

Download file